A new plant for the production of sterile non-cytotoxic drugs and innovative products for diseases outside of the field of oncology with the objective to support complex and integrated portfolio of products, with new modalities of action and new effective therapies.

Our capabilities are designed to handle SMALL and LARGE MOLECULES, SOLVENT BASED FORMULATION and LIPID BASED FORMULATION for development, clinical and commercial supply.

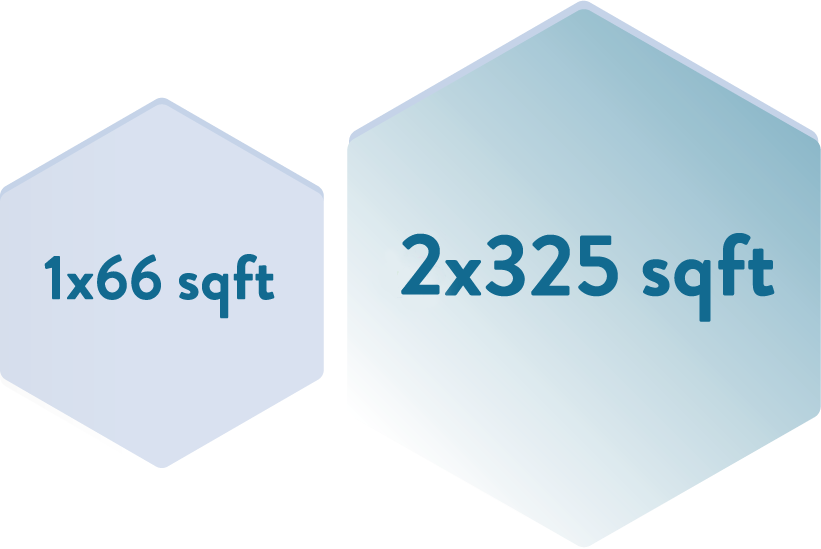

equipped to handle Liquid and Lyophilized vials from 2 ml to 100 ml with filling lines designed to manufacture products with short holding time and minimize shear stress.

DEDICATES AREAS FOR THAWING

STATIC AND DYNAMIC

TEMPERATURE CONTROL

DURING MANUFACTURING

CRYOGENIC LYOPHILIZERS

ENABLE A VERY ACCURATE AND EFFICIENT TEMPERATURE'S MANAGEMENT

DURING EACH STEP

AUTOMATIC LOADING & UNLOADING SYSTEM (ALUS)

DESIGNED FOR A RAPID INTRODUCTION OF THE VIALS INTO

THE LYO CHAMBER TO MINIMIZE PRODUCT'S EXPOSURE TO ROOM TEMPERATURE

100% CCIT BY FMS

VISUAL INSPECTION

MANUAL, SEMI-AUTOMATIC AND AUTOMATIC

SECONDARY PACKAGING available for Commercial supply and DEDICATED COLD STORAGE AREAS for DS, mAb, toxin and finish product (+2/+8°C; from -20°C up to -80°C) .